A Brief about Pressure Relief Valves

What is Pressure Relief Valves?

A Pressure Relief Valve (PRV) or relief valve is a type of safety valve that is used to control the pressure in a system that might otherwise disturb the process and consequently lead to system failures. It is designed to open at a pre-determined pressure level to protect other equipment from being damaged due to excess pressure. It aims at protecting property, life and environment.

What is the function of Pressure Relief Valves?

Normally, the pressure relief valve remains closed until pressure raises to the desired set pressure. When this level crosses, the valve opens and continues to further open and diverts the excess gas/ liquid to pass away. The valve closes again when the upstream pressure falls below the set pressure.

What are the Importance of Pressure Relief Valves?

Heavy gas equipment or industrial machineries that require gases at a certain set pressure level for proper mechanism can sometimes misbehave and if proper safety precautions are not observed may cause heavy loss to life and property. The most common causes of over-pressure are blocked discharge, thermal expansion, chemical reaction, cooling system failure, heat exchanger tube rupture, etc. These indents can happen suddenly at a much unexpected hour and may also take place simultaneously. Therefore installing the correct pressure relief valve is of utmost necessity. It is your responsibility to determine a scenario for the appropriate selection of the relief valve.

How to Select the Correct Pressure Relief Valve?

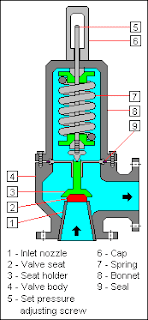

Mainly, there are two types of safety valves – Pilot operated safety valves & Spring loaded safety valves.

Pilot Operated Safety Valve

The pilot valve actuates at the set pressure and prevents medium from being routed to the vented dome. Due to the vents in the dome, closing force does not become a condition for system overpressure to push the main valve open and results in the opening of the main valve. The opening is either gradual and partial or rapid and complete. In case of drop in the system pressure, the pilot valve actuates and re-routs the medium to the dome, repeating its procedure.

Spring Loaded Pressure Relief Valve

In this types of valves, an increase in pressure results in increase in the spring force. The system pressure must raise enough to lift the valve. For this reason, most pressure relief valves are equipped with a secondary control chamber to enhance the lift by allowing fluid to enter the chamber that exposes a larger area of the disc to system pressure.

This causes an incremental force change that causes the valve to open at a rapid rate. Simultaneously, the direction of the fluid flow is reversed and the momentum thus created further enhances the lift. Due to this setting, the valve remains open until the pressure reduces to a level below the set pressure.